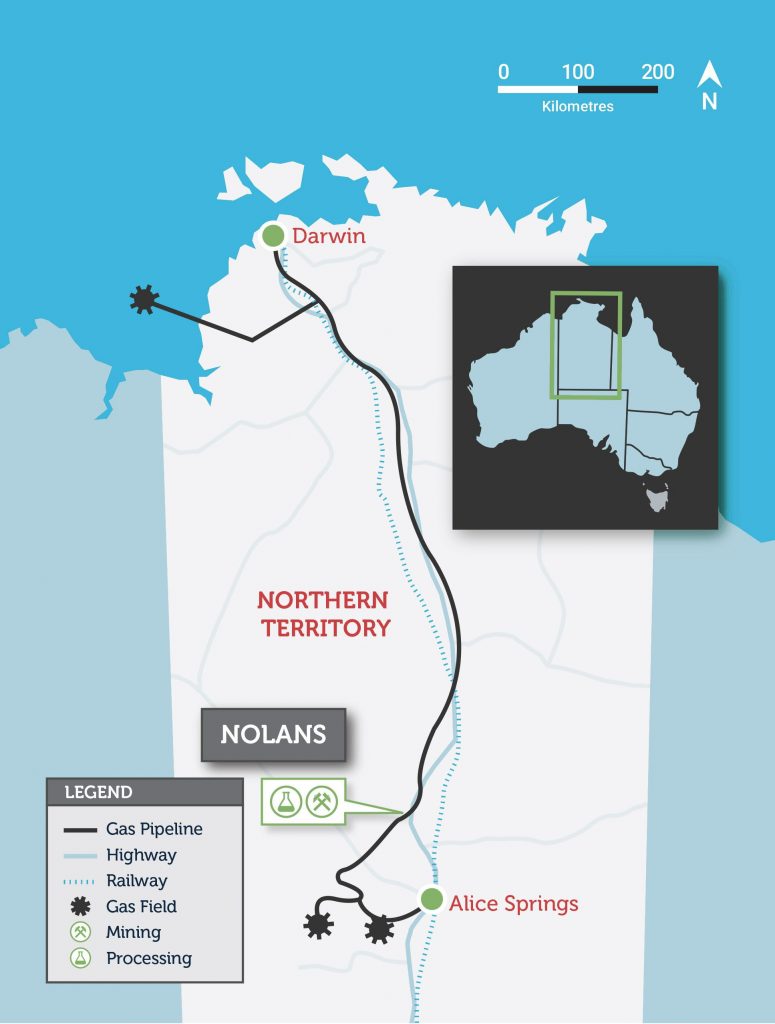

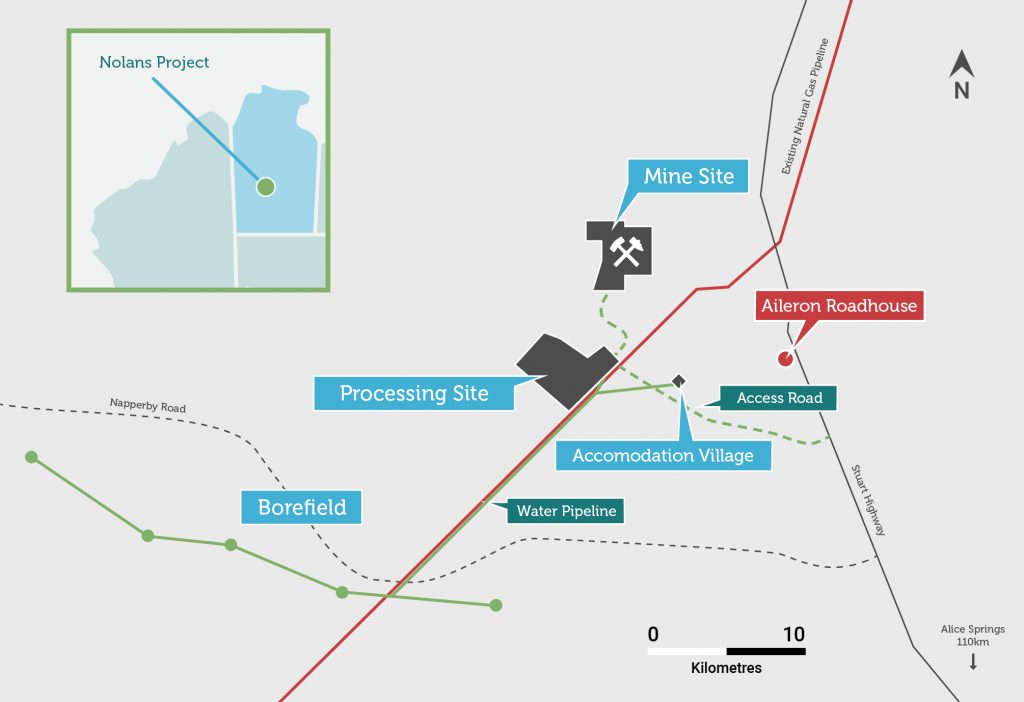

The Nolans Project will encompass a mine, process plant (comprising beneficiation, extraction and separation plants) and related infrastructure to be constructed and located at the Nolans site, 135 kilometres north of Alice Springs in Australia’s Northern Territory. The Project is underpinned by low-risk Mineral Resources that have the potential to supply a significant proportion of the world’s NdPr demand. It is a globally significant and strategic NdPr project which, once developed, will become a major supplier of these critical minerals to the high-performance NdFeB permanent magnet market.

The Project will benefit from its Australian domicile and its proximity to transport, water and energy infrastructure.

Resources and Reserves

The project’s cornerstone asset is the Nolans Bore rare earths-phosphate-uranium-thorium (REE-P-U-Th) deposit, one of the largest and most intensively explored deposits of its kind in the world. The deposit contains a JORC 2012-compliant Mineral Resources of 56 million tonnes at an average grade of 2.6% total rare earth oxides (TREO) and 11% phosphate (P2O5) that extends to 215 metres below the surface. Two-thirds of the contained rare earths are in high confidence Measured and Indicated resources.

NOLANS IS A WORLD CLASS, SHOVEL READY

AUSTRALIAN NdPr PROJECT THAT WILL SUPPLY ~4%

OF THE WORLD’S NdPr OXIDE DEMAND.

MINERAL RESOURCES FOR THE NOLANS BORE DEPOSIT AS AT 7 JUNE 2017 USING A 1% TREO CUT-OFF GRADE

| RESOURCES | TONNES million | RARE EARTHS TREO % | PHOSPHATE P2O5% | NdPr enrichment % |

|---|---|---|---|---|

| Measured | 4.9 | 3.2 | 13 | 26.1 |

| Indicated | 30 | 2.7 | 12 | 26.4 |

| Inferred | 21 | 2.3 | 10 | 26.5 |

| TOTAL | 56 | 2.6 | 11 | 26.4 |

ORE RESERVES FOR THE NOLANS PROJECT AS AT 16 MARCH 2020

| RESERVES | TONNES million | RARE EARTHS TREO % | PHOSPHATE P2O5 % | NdPr enrichment % |

|---|---|---|---|---|

| Proved | 5.0 | 3.0 | 13 | 26.2 |

| Probable | 24.6 | 2.8 | 13 | 26.5 |

| TOTAL | 29.5 | 2.9 | 13 | 26.4 |

Mining and Processing

The Mining Inventory has the potential to support mining and processing operations for 38 years at a design capacity of 340,000 tonnes of concentrate production per annum.

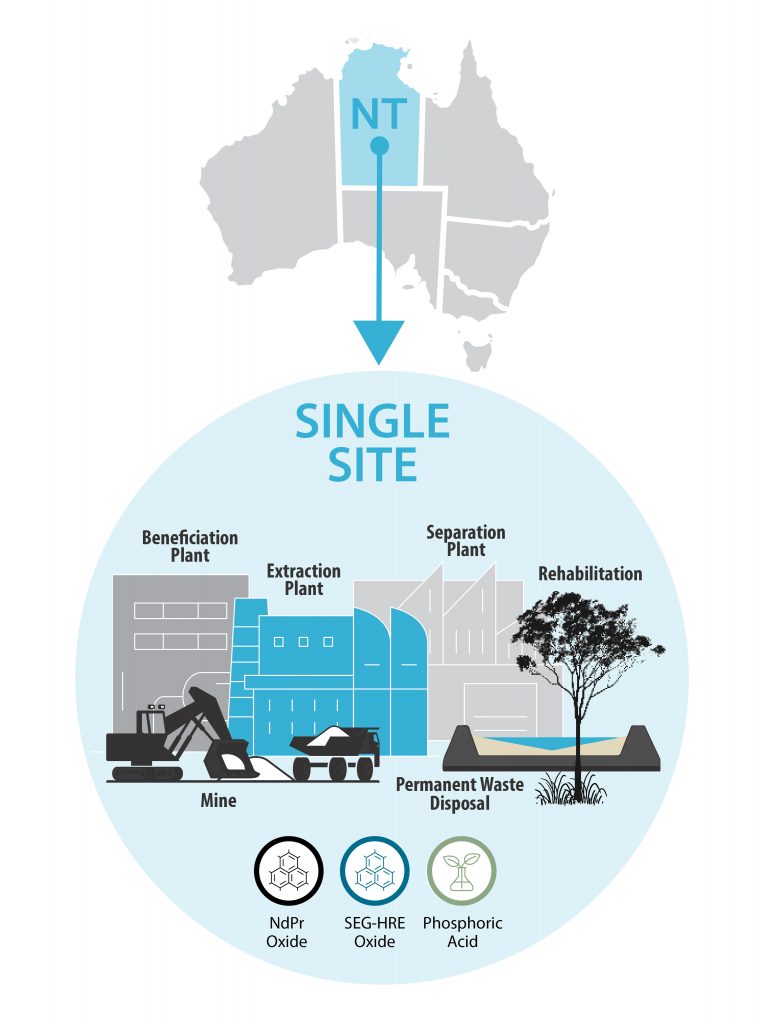

Open-cut mining will selectively target phosphate-rich material types in seven pit stages over the life of mine with ore being fed to a single-stage crushing and milling circuit at the process plant approximately 8.5 kilometres south of the mine.

Milled ore will initially be processed using flotation. This reduces the mass for subsequent processing and produces a phosphate-rich, rare earth-bearing concentrate, as well as tailings. Tailings will be pumped to a Residue Storage Facility (RSF) for containment and long-term management.

The concentrate will be fed to an adjacent extraction plant, where it will be subjected to a number of hydrometallurgical processes including pre-leach, sulphation, water leach, precipitation, dissolution, and purification. The extraction plant will produce 144,000 tonnes of fertilizer-grade (54%) phosphoric acid each year as a by-product of the pre-leach process. This product is earmarked for export and direct sale. Waste streams, including gypsum, from extraction processing will be neutralised before being pumped to an RSF.

Rare earth chloride from the extraction plant will be further refined at an adjacent separation plant into two final rare earth products for export and sale: 4,440 tonnes per annum of NdPr oxide and 470 tonnes per annum of a mixed middle-heavy rare earth (SEG/HRE) oxide.

Environment

The Nolans Project has been subject to Northern Territory and Australian environmental assessment processes administered by the Northern Territory Environment Protection Authority (NT EPA) and the Australian Government Department of the Environment and Energy (DoEE). The Company received environmental approval from the NT EPA in 2017 and from the DoEE in 2018. These rigorous and lengthy processes included an assessment of the Company’s ability to manage mine waste and process plant residues and to progressively rehabilitate the site, which has been fully costed.

Nolans is the only NdPr-focused project in Australia that has secured complete environmental permitting for mining, beneficiation, extraction and separation of rare earths, including the on-site management and disposal of attendant radioactive tailings and process wastes, as well as progressive site rehabilitation.

Community and Social Benefits

Nolans is expected to deliver substantial social and economic benefits to local, regional and national stakeholders. This will include indigenous and local employment opportunities, small and medium enterprise business opportunities, royalties and potentially shared infrastructure. The Company estimates the peak construction workforce will be 600 people with an operational workforce of 350. During steady state operations, most of the workforce will reside at site. However, the Project has the potential to accommodate community friendly rosters considering its proximity to the communities of Alice Springs, Ti Tree and Laramba.

In recognition of the Project’s national strategic significance the Australian Government renewed its Major Project Status in 2020 which provides a mechanism for coordinated access to a range of Australian Government services and programs which will assist in both the Project development as well as delivering benefits for local and regional stakeholders.

Mining Licence and Permitting

Australia’s mining and mineral processing industry is both mature and well-regulated having been developed over many decades under the stewardship of successive state and federal governments.

A Native Title Agreement (NTA) covering all parts of the Nolans Project has been executed in June 2020 with the site’s Native Title Holders. This NTA provides for the on-going protection of the Native Title Holders rights as well as allowing them to share in the long-term benefits of the Nolans Project.

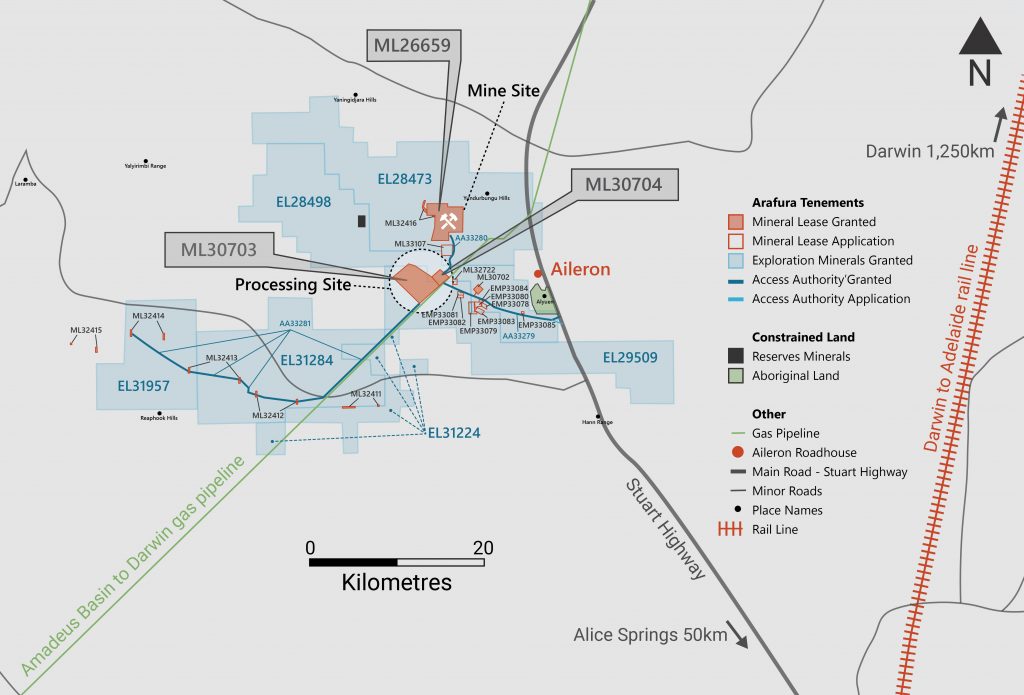

Following the execution of the NTA the Northern Territory Government granted the Project’s Mineral Leases (MLs) in July 2020 with the MLs for the borefield area granted in February 2021. These MLs provide Arafura tenure over the Nolans asset for 25 years and a licence to operate (subject to annual compliance reviews) for the same period.

During 2021/22 the Company prepared the Mining Management Plan and associated Environmental Management Plans which outlines the details of how the construction, operations and closure of the Project will be undertaken while minimising the impact on the surrounding environment and communities. The Company submitted these plans for approval to the Northern Territory Government in 2022 and in November 2022 received approval of these plans, which on payment of the assessed environmental bonds, grants the Company its Authority to Mine, the final permit required before commencing construction and operations.

The surrounding areas of the Project are covered by three exploration licences.

Project Development

Arafura’s focus is to procure the funds necessary to construct and operate the Nolans project in order to take full advantage of an anticipated mid-2020s supply shortfall in NdPr oxide.

An important and necessary precursor to a final investment decision (FID) is to finalise commercially-binding sales agreements for a large proportion of the project’s NdPr oxide product offering.

While funding and offtake activities are being finalised the company plans to complete front-end engineering and design in preparedness for FID.